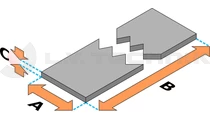

Anti-slip rubber mat 150 x 800 x 3mm

Advantage of anti-slip mats

The anti-slip mat is made of rubber granulate. Its purpose to increase the friction between the load and the adjoining surface, so less lashing strap is needed to secure the load. According to EN 12195-1 in case of anti-slip mat calculations can be made with μ=0.6 friction factor. In practice this value is higher, can be 0.8 or even higher. The exact value is difficult to determine as it depends on different factors as well (humidity, temperature, platform contamination etc...). Additional advantage is affordable price and long lifetime.

Example

We have to secure 4 pcs of cylindric metal part (4 ton each) on a semi-trailer. The metal parts are delivered in a wooden case and the platform is made of plywood. We have ERGO lashing straps with STF=500 daN and LC = 2500 daN, the strap has angle of 60° with the platform. How many lashing straps we need with and without using anti-slip mats?

The formula we have to calculate with

| number of lashing straps = | FZ × (c - μ) |

| STF × 2 × μ × sinα |

Variables

Friction factor (μ): The friction factor between the load and the adjoining surface decreases the force applied to the load. The bigger the friction is the more difficult for the load to move. In case of wood and plywood this factor has a value of 0.3, while in case of anti-slip mat it is 0.6.

STF: Residual force in the strap after release of the handle of the ratchet. The longer the ratchet is, the stronger force in the strap generated.

Calculation without anti-slip mat

| number of lashing straps = | 16000daN × (0.8 - 0.3) | = 31 |

| 500daN × 2 × 0.3 × sin60° |

As there are 4 identical parts - without anti-slip mat - 32 pcs of lashing strap needed.

Calculation with anti-slip mat

| number of lashing straps = | 16000daN × (0.8 - 0.6) | = 7 |

| 500daN × 2 × 0.6 × sin60° |

With anti-slip mats we are able to solve the load securing with 8 pcs of lashing strap (2 for each part).

When to change

If the anti-slip mat shows the signs of wear it is possible that the it cannot fulfill its duty anymore. In case of these signs the mat must be changed:

- permanent deformation or compression

- tear

- wear of surface or abrasion

- missing areask

- swollen areas

- loss of flexibility

- soiling that affects the function of the mats